Description:

Introduction

Novel technology developed at RCSI has produced an improved, facile,

low temperature and “green” technology for the production of racemic sulfonic

acids. Sulfonic acids are precious compounds that are present in a wide number

of marketed compounds such as taurine (used as a functional food in many energy

products and drinks, e.g., Red Bull) and saclophen (used in anti-spasmodic drugs

such a Lioresal). At present, their

production involves the reaction of alkenes and bisulfite at high temperature

and in the presence of radical initiators. The involvement of radical species

raises the risk of explosions and increases the costs of manufacture. The

proposed chemistry runs at room temperature and makes no use of radical

initiators. Additionally, the catalysts used are simple, inexpensive amines that

could be recovered and recycled at the end of the reaction by acid base wash.

Consequently, the technology allows for the preparation of sulfonic acids

without the need for heating-cooling equipment and peroxides as radical

initiators, making the preparation of the title compounds safer, cleaner and

more cost effective.

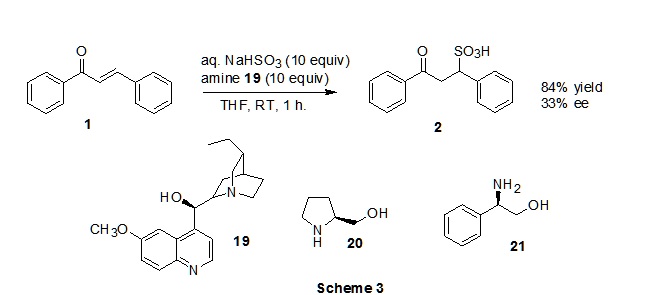

Technology

Amines in general and triethylamine in particular have been found to

enhance the addition of bisulfite to alkenes. Novel reaction conditions

conducted at RCSI have allowed the addition of bisulfite to alkenes to occur at

room temperature and without the need for radical initiators. A protocol leading

to enantio enriched sulfonic acid has now been developed for the first

time.

This novel technology provides:

1.

A “green” and practical methodology to prepare sulfonic acids that

are active ingredients in surfactants and commercially available soaps.

2.

A novel methodology producing sulfonic acids that are not available

using conventional methodologies, useful for the preparation of drug like

compounds.

3.

A method to prepare sulfonic acids in enantioselective pure

form.

Example of enantioselective addition of bisulfite to activated

alkenes

Applications

The invention may be exploited as a process to manufacture existing

compounds for example, taurine or saclophen; or as a technique to prepare

end-products, for instance chiral sulfonic acids could be used in the

preparation of enantiopure amines.

At present, two steps are required for the production of enantiopure

sulfonic acids (addition of bisulfite to alkenes and subsequent resolution).

RCSI’s technology has the potential to supply customers with a method to obtain

enantiopure sulfonic acids directly from alkenes using mild conditions. The

families of enantiopure sulfonic acids prepared in this way will be applicable

to drug discovery and the preparation of organic intermediates and, as such,

represents a platform technology

for the use of sulfonic acids. For example, sulfonic acids are “interchangeable”

with carboxylates and tetrazoles, two templates often present in active

ingredients. Hence, the technology proposed could enlarge the scope of

investigation of many medicinal chemistry projects involving these structural

elements.

Advantages

Advantages of this technology include excellent solvency and

compatibility, rich and fine foam production, ease of biodegradation, low

toxicity and low irritation to skin. In the application of non-phosphorus

detergents, the technology provides for both washing ability and compatibility

with enzyme agents. Powder (grain) shape products have good fluidity, therefore

they are widely used in non-phosphorus washing powder, liquid detergents and

home washing products, textile, printing and dyeing industry, petrochemical

products, and industrial hard surface cleaning agents.

The families of enantiopure sulfonic acids prepared in this project

will be of interest for those involved in drug discovery or in the preparation

of organic intermediates and in pharmaceuticals R&D.

|

Feature |

Benefit |

|

No need for radicals |

Increased safety during manufacturing

processes |

|

Low temperature reaction |

Reduced cost of manufacturing |

|

Catalysts are reusable |

Cheaper and for environmentally friendlt

process |

Contacts:

Dr. Gearóid Tuohy, RCSI Technology Transfer, 123 St Stephen’s Green, Dublin 2, Ireland.

Email: gearoidtuohy@rcsi.ie Tel: +353 1 4022362

Dr Aoife

Gallagher, RCSI Technology Transfer, 123 St Stephen’s Green, Dublin 2, Ireland.

Email: aoifegallagher1@rcsi.ie. Tel: +353 1 4022394

Dr Liz Moran,

Enterprise Ireland,

East Point Business Park, Dublin 3.

Email: liz.moran@enterprise-ireland.com.

Tel: +353 1 7272696

Principle Investigator:

Dr. Mauro Adamo,

Department of Pharmaceutical & Medicinal Chemistry, Royal College of

Surgeons, 123 St Stephen’s Green, Dublin 2,

Ireland. Email: madamo@rcsi.ie. Tel:

+353 1 4022208